A TEQUILA FOR EVERYONE

We don’t simply produce tequila. We create it. Espolòn Tequila is the life-long aspiration of Maestro Tequilero, Cirilo Oropeza. Combining a background in chemical engineering and over 50 years of distilling experience, Cirilo blends the science of distilling with the art of tequila making.

With a revolutionary spirit, strict attention to detail and his renowned unconventional methods, Cirilo had one simple goal: to create a tequila so good he was proud to share it with the world. Espolòn is that tequila.

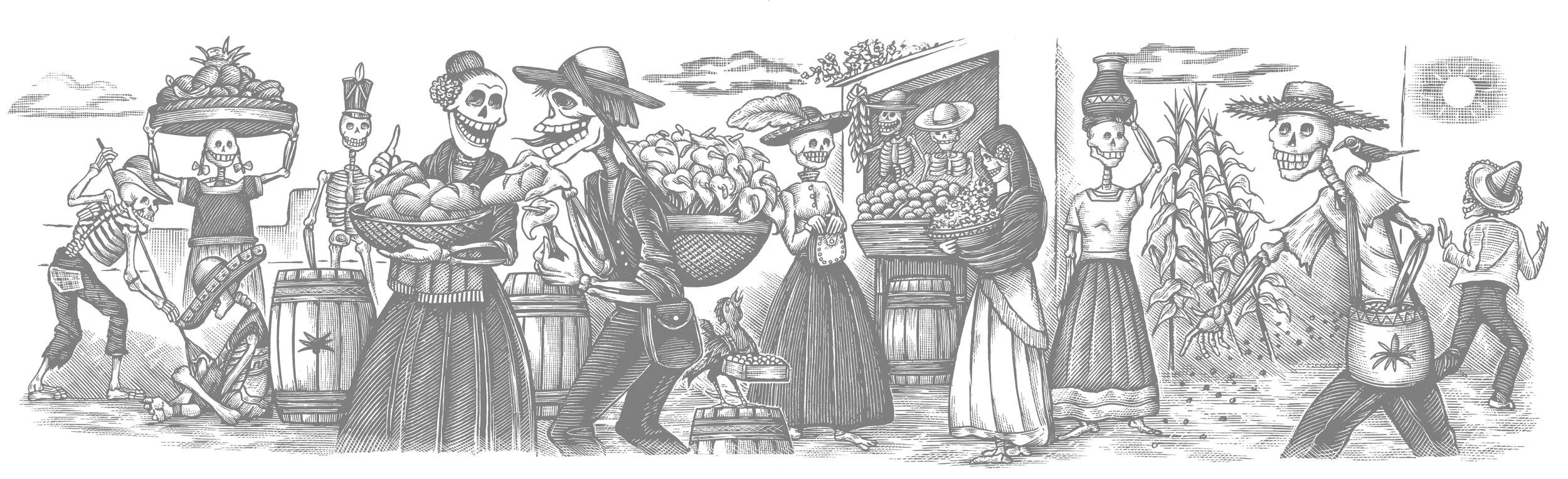

Named for the spur of the iconic rooster in Mexico, a national symbol of pride, and packaged in a spirited salute to the art of legendary José Guadalupe Posada, the tequilas of Espolòn are a powerful tribute to the true storied culture of Mexico itself.

Like any good Maestro, Cirilo has his secrets. But he’s proud to share the keys to making his beloved Espolòn: an exceptional premium tequila accessible to everyone.

Our Distillery

Our Casa San Nicolás (NOM: 1440) is located 2,000m above sea level in the Highlands of Jalisco, Mexico. It was built to unleash Cirilo with everything he needs to chase his dream. The dream, creating a superior tequila for everyone to enjoy.

The Plascencia family has roots in the tequila industry dating back to 1898. Don Celso Plascencia was a humble working man born in the Highlands. He worked the land and, as he traveled to and from the fields that belonged to other men, he promised that one day his family would own their own estate and make their own tequila. In 1996, Don Celso’s grandson Raul Plascencia fulfilled this dream with the completion of Casa San Nicolás.

To lead the operation, Plascencia tapped Cirilo Oropeza, whose undeniable talent and steadfast commitment to quality distillation made him the perfect match. The facilities at San Nicolás are a perfect blend of both artisanal Mexican tradition and efficient modern technology.

Our Agave

Only 100% Blue Weber Agave goes in our tequila. Our farmers hand-harvest the piñas when the agave’s matured and they’ve got the higher sugar content that’s perfect for making tequila.

After harvest, a quality inspection is carried out. Once the piñas pass inspection, the leaves are cut in the field to meet our low-cut specifications – this removes any undesirable oils and flavors – a crucial step to maintaining the unique taste of our tequilas. The piñas are then chopped down into smaller pieces for more surface area to extract the sugars during cooking.

Our WATER

Deep down, around 250 meters beneath the Highlands of Jalisco, our water is busy soaking up the natural bounty that only the Highlands can provide.

Every drop of water that goes into our tequila is as pure as it is when it comes out of our well. We make sure not to filter out the rich and flavourful natural elements. We’ve found that this deep connection to Mexico’s natural environment is a crucial ingredient in Espolòn’s award-winning flavor.

Our Cooking

Our Maestro Tequilero Cirilo demands a taste profile that's smooth, delicate yet complex with sweet cooked notes. Brick ovens would deliver too much smoke, and diffusers would not caramelize the agave enough to give us those sweet notes we need. It’s one of the many reasons we don’t use diffusers in our production process.

Our tequila needed a better solution, and Cirilo delivered. Using his chemical engineering background, Cirilo custom designed stainless-steel autoclaves; pressure chambers that cook with consistent temperature and steam pressure, to produce more even caramelization. As the piñas cook, they soften, and the sugars begin to seep out from the hearts. Pipes below the autoclaves collect these sugars and separate the sweet honey from the bitter honey. The sweet honey is added later in the process to deliver Espolòn's signature flavor profile.

Our Milling

The cooked piñas are run through our roller mills, where they are ground up to extract the sugars from the fibrous pulp: the bagasse. Then we measure the brix, or sugar content by hand, to maintain consistency. After the sugar is extracted, the leftover bagasse is turned into fertilizer and some is given to local farmers for future crops.

We only run our piñas through this system once, and the sugary juice we call jugo, is sent to the fermentation tanks.

Our Fermentation

There is no better example of blending science with art than our unique fermentation process. We begin by fermenting the jugo with our specific strain of yeast in open stainless-steel tanks for between 70-80 hours (3-4 days). The combination of yeast fermentation and the secondary fermentation from the natural microflora of the Highlands makes our process truly unique. Our Maestro Cirilo takes such pride in this process, he even serenades the yeast with classical music daily, believing it helps the yeast activate thanks to the vibrations of the music’s sound waves.

Cirilo’s experience creates a one-of-a-kind fermentation that plays a very important role to create our award-winning flavor. Some will say, “If it’s not broken, don’t fix it.” But not Cirilo. As Espolòn’s popularity grows around the globe, Cirilo is proud to work every day to guarantee the highest quality tequila. His legacy inspires us to continually experiment and try to make our tequila even better, studying it on a molecular level to understand the changes to the flavor profile each day during the fermentation process.

Our Distilling

For Espolòn Tequila, we use a combination of pot and column still distillation – both the pot & column distillates are distilled twice. Pot stills are more traditional and produce an earthy taste profile, and our use of a column still enables us to get a clean, light and fruity distillate. During the pot still distillation, the mosto, or agave juice, is distilled twice in our stainless-steel pot stills with copper reactors.

Cirilo uses his experience to split the heads and tails each time, in a unique way, only extracting the alcohol we want. Then Cirilo works the column still as if it were a musical instrument: adjusting the flow, temperature, pressure, and reflux to play flavors as notes. It’s Cirilo’s passion and dedication to every step in our distillation process that makes it an art, creating a truly unique tequila and drinking experience.

Our BLENDING

Our Maestro Tequilero Cirilo marries the finest cuts from both distillations to make a bold, balanced, and approachable blanco tequila. Each distillation adds unique notes to the flavor profile. The pot distillate brings earthy, mineral, herbaceous, vegetal, and spicy flavors while the column still gives us fruity, sweet, creamy, caramelized, and fresh agave flavors.

For blanco, the liquid is then diluted to set the final alcohol strength and bottled. For our aged expressions, we transfer the liquid into #2 char American Oak Barrels at high alcohol by volume, which means less water gets added before bottling, to lock in more of our tequila flavor.

Our Barrel Aging

Our tequilas are unique works of art perfected by time. For the rich, complex, well-rounded and unique Espolòn flavors, we only age in #2 char American Oak barrels. Our tequila goes into the barrel at 42% ABV, so we add less water before bottling, making sure our tequila flavor shows up in a big way. We never add anything that shouldn’t be in tequila.

Our reposado spends at least two months in a barrel, and our añejo spends at least a year before being transferred to a used Wild Turkey Bourbon barrel for two months to finish. For our añejo X, it takes at least six years to achieve the depth and complexity of this limited-edition tequila of uncommon character.

As a final measure before any drop of tequila is bottled, an on-site team, handpicked and trained by Cirilo himself, tests every batch – making sure it’s ready to wear Espolòn’s striking label.